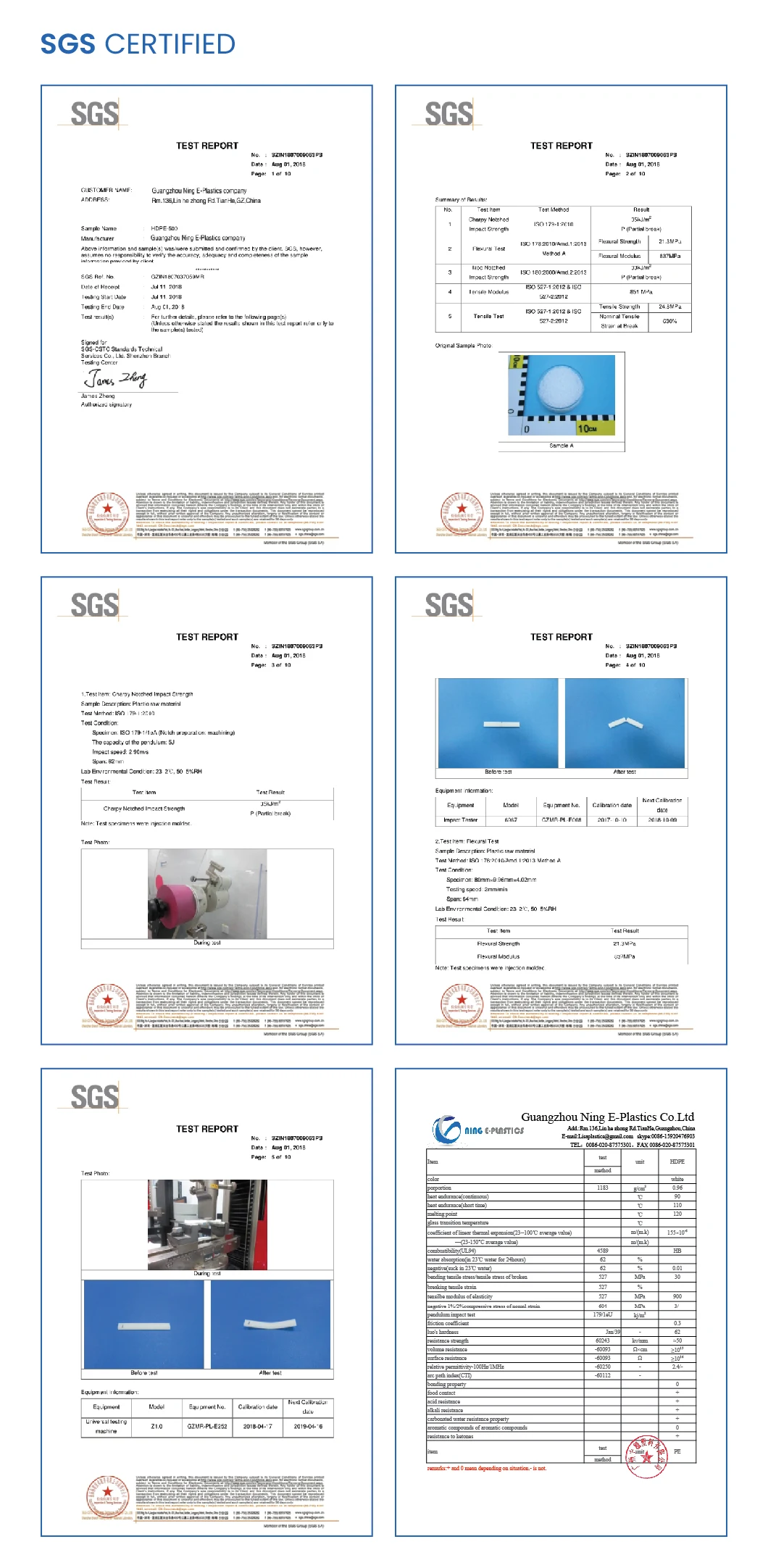

Engineering Plastic Boards, HDPE /Polyethlene/a Cetal/ABS/Nylon/PA6g/POM Sheets

Basic Info

| Model NO. | PE001 |

| Tensile Strength | 51~80MPa |

| Density | 1.6 |

| Transport Package | 1000kgs/Pallet |

| Specification | 1220*2440mm/customized |

| Trademark | without logo |

| Origin | China |

| HS Code | 3918909000 |

| Production Capacity | 1000000 /Per Months |

Product Description

HDPE Sheet

Colour : Black /white /red/yellow/orange/blue

HDPE Sheet Thickness: 2-200 mm, 0.2-3 mm

HDPE Sheet Size: 1220 mm×2440mm, 1000×2000 mm

High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low coefficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). The material's durability makes it a perfect match for a variety of applications such as water tanks, chute linings, bottle/bottle cap production and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

Product Description

High-density Poly Ethylene also is known as HDPE is made from a cord of ethylene molecules (the poly part of polyethylene), and is famous for its light weight and high durability.

The preference of HDPE sheets is increasing from leaps and bounds in the market today, as it's able to cut down on the material which is then used for producing and packaging products for its strength and weight.

It is also available at tap plastics in sheet form with either a smooth or textured surface. The textured surface is also called cutting board. Both smooth and textured surfaces are FDA approved for food contact.

Types of HDPE Sheet

HDPE sheets are expanded into multiple types, each type has different applications and uses such as;

HDPE Matte Sheet

HDPE sheet comes with a textured surface which is also known as HDPE Matte sheet. This type of sheet is designed to produce items like cutting boards. HDPE Matte is acid resistant, reliable with FDA controls, and certified by the National Sanitation Foundation .

It is best for food preparation as it won't make your knives dull, and it doesn't harbor bacteria as well.

HDPE Smooth Sheet

Smooth HDPE sheeting is ideal for those applications which need good abrasion resistance and low friction. It comprises of multiple features which make it versatile for many applications. The best, yet the most common example of smooth HDPE sheet application is, tank linking.

Smooth HDPE is effortlessly created and includes great compound protection, elasticity, and is dampness and effect safe.

HDPE Pipe Grade

This kind of HDPE plastic sheet features more advance performance than standard HDPE sheeting. The enhanced highlights of HDPE pipe grade make it the most well-known HDPE sheet for open air applications.

| Item | RESULT | UNIT | PARAMETER | NORM USED |

| Mechanical properties | ||||

| Modulus of elasticity | 1000 | MPa | In tension | DIN EN ISO 527-2 |

| Modulus of elasticity | 1000 - 1400 | MPa | In flexure | DIN EN ISO 527-2 |

| Tensile strength at yield | 25 | MPa | 50 mm/min | DIN EN ISO 527-2 |

| Impact strength (Charpy) | 140 | Kj/m 2 | Max. 7,5j | |

| Notched Impact stren. (Charpy) | No break | Kj/m 2 | Max. 7,5j | |

| Ball indentation hardness | 50 | MPa | ISO 2039-1 | |

| Creep rupture strength | 12,50 | MPa | After 1000 hours static load 1% elong. after 1000 hours Against steel p=0,05 N/mm 2 | |

| Time yield limit | 3 | MPa | ||

| Coefficient of friction | 0,29 | ------ | ||

| Thermal properties | ||||

| Glass transition temperature | -95 | °C | DIN 53765 | |

| Crystalline melting point | 130 | °C | DIN 53765 | |

| Service temperature | 90 | °C | Short term | |

| Service temperature | 80 | °C | Long term | |

| Thermal expansion | 13 - 15 | 10-5K-1 | DIN 53483 | |

| Specific heat | 1,70 - 2,00 | J/(g+K) | ISO 22007-4:2008 | |

| Thermal conductivity | 0,35 - 0,43 | W/(K+m) | ISO 22007-4:2008 | |

| Heat distorsion temperature | 42 - 49 | °C | Method A | R75 |

| Heat distorsion temperature | 70 - 85 | °C | Method B | R75 |

FAQ

1.

Q: What is your delivery time?

A: It depends on the volume, usually it is about 7 days.

2.

Q: How can I get a sample?

A: Small size of sample are free, you only need to pay for the shipping cost, or you can provide your UPS, DHL, Fedex, TNT courier account to us. Customized size of sample should be charged.

3.

Q: What is your payment ?

A:30% T/T in advance, balance before shipment. Other terms negotiable.